Human Organs-on-Chips: easier said than done

Jun 25, 2020

Posted by: Valon Llabjani

By Dr. Valon Llabjani, Founder and CEO of Revivocell Limited

From a Petri dish to an organ-on-a-chip, is it a big jump? Want to know more about the current state of the art in organs-on-a-chip technologies? And, how they compare to conventional cell culture methods? Have they advanced to really build whole organ functions or just an approach to recreate histological sections? Are there technologies that can bridge this gap with higher throughput, reproducible data, easy to adapt and lower cost? This article will shed light on these questions and more. I will share the most recent advancements in organ-on-a-chip approaches and why they need improvements before they can widely be adapted in the laboratories. Finally, you will learn about Revivocell’s CELLBLOKS® technology as a new tool to bridge the gap between conventional methods and organs-on-a-chip approaches.

Cell culture

Cell culture involves the growth of living cells in laboratory conditions, in-vitro, without using animals in order to gain better understanding of body function, disease or to develop new drugs. The technology has been used for pre-clinical drug screening to test safety and efficacy of new drugs as well as tissue engineering, molecular diagnostics and defence application, amongst others.

In-vitro cell-based models have become indispensable in drug screening in order to select most promising candidates for further development and screen for toxicity issues early, before reaching clinical trials. However, rising cost-to-delivery ratios and the poor predictive value of existing in-vitro and in-vivo tests is creating demand for more realistic laboratory models.

Despite current advances, the cost of new drug discovery is continuously increasing; it now takes more than 10-15 years and costs more than $2bn to get a new drug to market, with only ~10% success rate.

In the last decade organ-on-a-chip microfluidics technology have been proposed as an alternative approach to conventional cell culture methods in order to better replicate in-vivo body like conditions by combining advances in biophysical engineering and recent development in 3-D cell culture technology.

Most relevant studies are those in-vivo because they represent the whole systematic body function. However, in-vivo studies are challenging due the complexity to understand physiological mechanism of action and have low throughput, in addition to ethical considerations. In drug discovery, thousands of compounds are screened in high-throughput manner for their efficacy and safety, and this would not be possible in direct in-vivo studies. Current preclinical in-vivo animal models often fail to predict drug adverse reactions in humans (eg., hepatotoxicity by 50-60% ) due to substantial differences of drug metabolising enzymes between animals and humans, and existing in- vitro cell culture models do not represent complex organotypic conditions; making in-vitro approaches that better replicate living tissues highly desirable.

Convention cell culture

Conventionally cells are been grown in hard and flat 2-D surfaces, either on glass or plastic, and this technology has not changed significantly since the invention of the Petri dish by Julius Richard Petrie in 1870s. Traditionally cell culture has been performed in macro-culture systems, which include Petri dishes, tissue culture flasks, cell culture dishes, multi-well plates and well inserts. They are still used as a “gold standard” for preliminary screening in drug discovery such as cytotoxicity as well other life sciences applications. Furthermore, they have been well optimised with time and much of the available equipment has been particularly adapted for this format, making them as a standard across labs. The main advantage of traditional culture that they are well established in their material properties, are standardised for controlling cell culture conditions (i.e, pH, CO2 and O2), can be quickly scaled up and are adapted for vast number of assay endpoints. In addition, cell culturing protocols have been well optimised and standardised making the data more comparable and reproducible across different labs.

Although, traditional cell culture has played a vital role in many life science discoveries such as the development of new drugs or vaccines, the results often lack efficiency as cell function due to their growth being constrained is single cultures and the available 2-D surface when compared to true three-dimensional (3-D) complex multicellular environments of living tissues. They have limited scope to adopt natural morphologies or to participate in cell-to-cell communication reflective of multiple cell nature of real organs. This impacts upon the validity of data generated and how representative it is of in-vivo circumstances.

And thus, they lack the ability to incorporate multiple cell types important in maintain tissue homeostasis. Cells cultured in such format can quickly lose their responsiveness and function and fail to account for the interaction of different organs and cell types that cannot be directly evaluated. No cell lives alone in the human body and creating a multiple cell type tissue models are essential to mimic the true nature of organ specific functions. This is still challenging and requires further development.

Organ-on-a-chip technologies

Organ-on-a-chip technology aims to create organ like conditions in a laboratory setting by using micro-chips for more precise control of cell culture conditions including flow rate, surface chemistry, fluid/gas exchange as well as mechanical and electrical stimuli. And such the technology could be a significant tool for understanding the dysfunction and pathology of the body, making it useful for a variety of applications including medicine, oncology and pharmacology. The idea is to more closely replicate microenvironments of real organs, and number of studies have focused simulating liver-on-a-chip, brain-on-a-chip, lung-on-chip, heart on-a-chip, cancer-on-a chip etc. The future goal is to connect multiple organ-chips together with vascular flow, creating “human-on-a-chip”.

The size of a chip is generally about the standard microscope glass slide, 75mm x 25mm (3” by 1”) and the flow is limited to small 10-9 to 10-18 litres using micrometre channels engraved in the devices. The main advantage lays in the precise control parameters that could make it more physiologically relevant and include microflow that matching real exposure volumes as well as accurately controlled administration of nutrients, test substances and removal of waste products at the right time. In addition, the inner surfaces of the chips can be modified to allow for 3-D cell culture growth, cell location patterning and the mechanical stimuli such as pulsation techniques, are improving and could add another dimensions not available in standard tissue culture formats. For instance, a section of a “breathable lung” is simulated by using a stretchable membrane which allows the growth of alveoli epithelial cells top side and vascular endothelial cells on the bottom sides. Using a precision pump media is then flown on the blood vessel side and expansion and contraction of the alveoli. Although this represent a major in control technology, the chip area is allows a small layer of growing cells. It only mimics a subset "histological section" of lung function rather than complex lung microenvironment containing not only vascular and alveoli cells but also other cell types including immune compartments and interactions from other organs.

What are the limitations of current organ-on-a-chip approaches

Despite the current advances in organ-on-a-chip microfluidics platforms they do not currently replace animal testing for drug discovery applications. Main barriers to uptake include engineering limitations, biological assay output, their practicality and cost of adaptation.

The focus has been more on miniaturisation and developing engineering solutions which has made them difficult to use and adapt, rather than creating functional systems that solve real biological problems.

Limitations include:

-

Limited endpoint measurement: The number of physiological responses that can be measured to a biological stimulus (eg., a test drug) within a microfluidic device are a few. The measurements are mainly sensor based and incorporated sensors are only limited to a few available endpoints. Due to a small sample size the number of cells accessible for further biochemical assays is very limited. Furthermore, collection of samples within the chip may interfere with the operation and concentrations of various metabolites. They need more suitable sensors and methods of sample collection without disturbing the experiments.

-

Complex operational control: Although the domain of the device is in microscale other handling equipment of a macroscale are required to run the platforms, including precision pumps, incubators and readout equipment making it more difficult to adapt and expensive to set-up. In addition, the complex chip designs with microfluidic networks makes them not compatible with standard pipette-friendly handling interface. This decreases the throughput and adaptability for standard applications. Furthermore, with microscales and complex operational controls the risk of errors and jeopardising the whole experiment increase costing time and resources. They need to incorporate cell manipulation capability within the platform in order to increase throughput and practicality.

-

Lack compatibility with standard workflow: Different platforms are provided by different suppliers which do not fit with standard readout equipment. Chips are made of new material surfaces (e.g., PDMS) not present in standard plates and currently are not standardised across different laboratories. No standards yet exist for interfacing with the current macro-world.

-

Cost of adaptation: The cost of manufacturing the chips and the required monitoring/handling equipment and consumables (i.e., new sensors) are relatively expensive comparted to standard tissue culture ware. The current starting price of around £20,000 makes their adaptions limited for widespread use and do not meet the need for different applications and research groups.

-

Lack of flexibility: Given that the platforms require attachments to operational equipment and usually provided in closed top/lid system, it makes it very difficult to access the cultures and change experimental conditions once the experiment is set-up. Platforms need to allow users to change conditions with time, eg., add another cell type or remove compartments for analysis in order to allow intuitive trial and error testing which is necessary in undersetting biological interactions.

The future of organs-on-chips

Although, individual organ-on-a-chip technology has advanced considerably in the last decade, connecting multiple organs still presents a major step that needs development. Scaling laws become more challenging when simultaneously scaling for different interconnected organs at once in a microchip format, in addition, to scaling for dynamic controls such as the pumping heart, contracting/expanding of the lungs. Further complexity is added when interpreting systems biology interactions which are enormously challenging to understand and translate to in-vivo scenarios.

It is more appropriate to scale each organ physiologically functionable rather than aiming to micro or nano scale the platform and dynamic media flows, which might induce false results not experienced in-vivo. The aim of “Functional scaling” is to replicate subset of organotypic functions rather that multiple organ conditions.

Small physiological sections might not represent complexity of an organ as a whole and be missing essential biological features but they could serve a test model for known biological responses.

The functional parameters to be simulated in-vitro should be first defined (e.g., a pumping heart, gas exchanged in lungs, liver metabolism or blood brain barrier) then the physical properties of the platform should then be iteratively tested both in macro and micro scales in order to achieve optimal output that reflect in-vivo responses rather than being constrained to physical architecture, materials and availability of cells. Although there are benefits of scaling in terms of reducing number of consumables used but the chances of errors are higher compared to macroscale cell culture. This is because more cells are likely to better represent in-vivo heterogeneity compared to few cells in microchips which could induce more inter-experimental variability, consequently reducing reliability and reproducibility.

Organ/human on chip technologies need scaling to reflect realistic physiology before they can replicate human organ functions in-vivo. Whilst organs-on-a chip engineering technologies are improving they are never likely to replicate millions of years of evolutionary engineering of human or even single organs. They should in the future be best viewed as simplified models for systems biology.

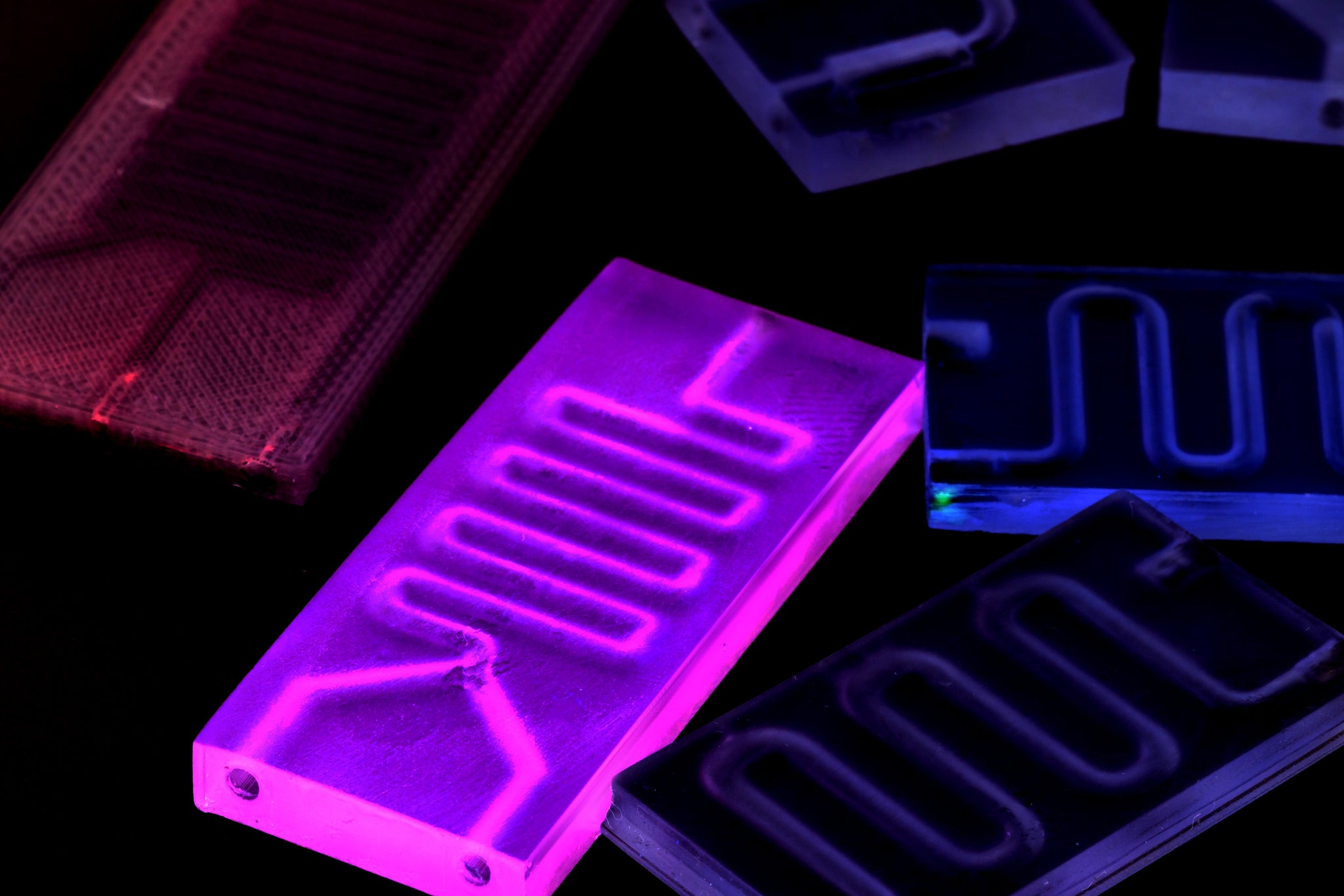

CELLBLOKS® Plug & Play technology

Revivocell’s CELLBLOKS® technology aims to bridge the gap between traditional cell culture technology and newer organ-on-a-chip devices, by overcoming some of the challenges associated with both approaches.

CELLBLOKS®, is a modular multi-organ/cell type LEGO®-like “Plug and Play” co-culture technology. It serves the purpose of emulating the organ environments in a standard in-vitro setting. It provides the feasibility of studying the assays in a 2-D and 3-D cell growth condition, and in static or flow system by using a standard perfusion rocker. Using CELLBLOKS the interaction between different organ specific cell can be directly evaluated as each cell type is grown in separate compartments whilst they are communicating via a shared media channel.

CELLBLOKS® platform is both compatible with existing equipment and standard protocols. In addition, the system allows easy access from the top enabling contentious observation of experiments meaning you can measure and alter experimental conditions over long time without disturbing other cells in culture. Individual cell growth blocks can be removed and substituted at any time during the experimentation.

The platform is cost effective and easily adaptable for different experiments and cell types. The technology aims to increase the success rate of developing new treatments and reduce the reliance on animal testing. CELLBLOKS® will provide a reliable, fast and cost-effective device that could be used in wide range applications including pre-clinical drug screening, tissue engineering, cell migration and communication studies amongst others.

Range of CELLBLOKS® platform kits designed to simulate both barrier and not barrier organs functions are available to order online.